So, you have decided to commence a predictive maintenance program (PdM). Excellent! Welcome to the exciting world of predictive maintenance and analytics. It’s power to revolutionise the way your plant operates; its financial outlook and longevity cannot be disputed.

In choosing to commence a PdM it’s highly likely you already have a champion internally for digital transformation. We believe it is important to gather the right team from the outset and start creating an internal culture that is excited about this digital change and a new way of working.

There are a number of steps to take before you’ll start to reap the benefits of your hard work;

Choosing your first pilot asset is a critical decision. In selecting the asset(s) it is important to consider the following;

Whilst whole of enterprise predictive maintenance programs are the end goal, so you can have an optimised plant, initially choosing one or two critical assets to run your pilot on is ideal. This way your project will be more manageable and you can apply your learnings to future roll-outs. This approach also ensures that your plant can keep operating and producing without being subject to any project delays.

Ideally during plant construction or the installation of any major machinery sufficient planning has been done to ensure suitable IoT sensors have been installed, enabling the future plant optimisation. If not, sensors can be retrofitted to your assets.

IoT sensors provide real time data on how your machinery is performing which is necessary for predictive analytics algorithms to run. A single crane with 2,500 sensors can produce 4 billion data points in one year. When it comes to the data produced from sensors, there is no such thing as too much data – in fact the more the merrier, and the more accurate the results.

The most common type of IoT Sensors are;

Ensuring you install the right type of sensor is critical to the success of your PdM, here at VROC we regularly consult on IoT sensors and can assist with their installation and commissioning.

Now that you have your live IoT sensor data, you need to gather all your historical data. This can include machinery manuals, operator working knowledge, maintenance logs, data from historians or databases.

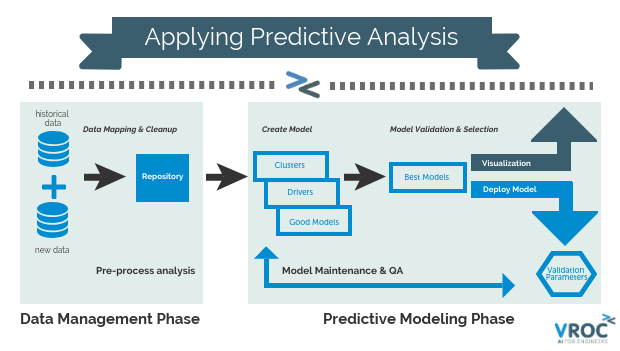

As you are dealing with differing data sets of different quality, along with new live data we recommend that you create a data lake. Check out our article on why you need a data lake here. A data lake accepts structured, unstructured or semi-structured data, and it accepts raw data. This actually provides optimum flexibility for your data scientist to run predictive analytics algorithms.

At this stage of your project allow time for data mapping and a thorough data clean-up, ensuring your data is reliable and integral.

Your data scientist will use an AI powered predictive maintenance software to formulate the problem statement, building models from your data. The benefit of AI and machine learning powered predictive maintenance is that the team has the power to draw from historical and live data, finding correlations which otherwise may not have been considered and at a mind boggling speed.

Selecting an AI powered predictive maintenance software is a key decision for your predictive maintenance program. VROC Predict provides your team with real time insights that helps you make business critical decisions for your assets. It provides the flexibility to build models using your historical and live data that help predict when your assets will fail.

Some companies choose to build their own AI platform, if choosing to do so, you’re company will embark upon that development piece as a unique project before commencing PdM. If still deciding on your approach, check out our article on Build vs Buy.

Once your team is confident with the live data, imported all the historical data and has built and tested AI models it is time to launch your pilot PdM. Your Predictive Maintenance models will make predictions on time to failure, identifying root cause down to the specific sensor. Your team will analyse these predictions and validate them, passing on key learnings and summaries to management as well as the maintenance teams.

The change from reactive maintenance or preventative maintenance to predictive maintenance is a significant change to how your business operates. Your team’s resources can be re-aligned to focus on plant optimisation rather than reactive measures to keep the plant operating.

New workflow process can be adopted and rolled out as the confidence in AI and Machine learning predictive analytics grows. Real time notifications are sent to staff, alerting them when conditions deviate from established thresholds, giving a prediction on time to failure in the next 7 days, allowing sufficient time for maintenance to be scheduled.

Adopting a workflow that includes continuous improvement is essential in order for PdM to be rolled out across an entire plant. It is essential to document your process and rational for decisions and key learnings so that a business case can be put forward to support the growth of PdM.

If properly implemented, Predictive Maintenance can put a stop to all unplanned shutdowns, a significant improvement to safety of all staff and the environment, as well as an increase to plant productivity. One of VROC’s oil and gas clients saw the following value increases through predictive analytics in 5 short months;

This is only one small example of the improvements that can ben seen through the application of predictive maintenance.

If you are commencing your predictive maintenance journey or struggling to see the expected value in your program at the moment, we’d love to hear from you. Get in touch today.

Learn the differences between predictive, preventive, and reactive maintenance. Compare costs, benefits, and risks

Read ArticleHow to confidently move from pilot to enterprise-wide AI adoption

Read ArticleInterested in a demo of one of our data solution products?

DataHUB4.0 is our enterprise data historian solution, OPUS is our Auto AI platform and OASIS is our remote control solution for Smart Cities and Facilities.

Book your demo with our team today!

Complete the form below and we’ll connect you with the right VROC expert to discuss your project. Whether you’re launching a pilot, scaling AI across your enterprise, or integrating complex systems, we’ll help you turn your data into actionable insights—fast, efficiently, and with confidence.

The efficient deployment, continuous retraining of models with live data and monitoring of model accuracy falls under the categorisation called MLOps. As businesses have hundreds and even.

Learn more about DataHUB+, VROC's enterprise data historian and visualization platform. Complete the form to download the product sheet.

Learn how OASIS unifies your systems, streams real-time data, and gives you full control of your smart facility—remotely and efficiently. Complete the form to access the product sheet.

Discover how OPUS, VROC’s no-code Industrial AI platform, turns your operational data into actionable insights. Complete the form below to access the product sheet and learn how you can predict failures, optimise processes, and accelerate AI adoption across your facility.

Interested in reading the technical case studies? Complete the form and our team will be in touch with you.

Subscribe to our newsletter for quarterly VROC updates and industry news.