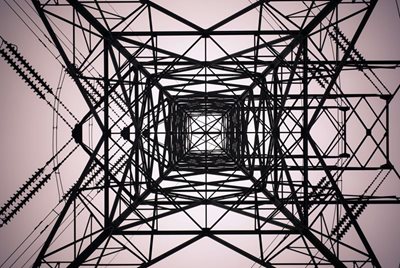

With fundamental shifts in the way the energy industry operates, the pressure is on to innovate and excel. Power needs to be generated faster, more efficiently and transmitted with less outages, to more people, with less environmental impact and safety incidents. The right methods must be found to manage the rising number of gigawatts needed to keep the lights on and our world running. From traditional to renewable, from old to new, from generation to transmission and distribution – we need to identify how things can simply be done better.

So what can technology do to enable this transition? Can assets be better managed, shutdowns and blackouts prevented, load forecasts and failures predicted? As the energy industry embarks on it’s journey of digital transformation, the question we’re asking is ‘what can artificial intelligence do to enable and empower the right kind of change?’. We’ve put together some of the best case studies we’ve seen on how AI is changing the game for the energy industry.

AI enabled hardware is a distinguishing characteristic of innovative energy companies. When Envision Energy started to design and manufacture wind turbines in 2007, CEO Zhang Lei realised early on that digital enablement was key if he wanted the asset his company produced to stand apart from competitors. The wind turbines his company produced were 'smart', with each one containing up to 500 sensors that monitored variables like wind speed and direction with the ability to make real-time adjustments, like changing the pitch of the blades. Small adjustments like this lead to increases in energy production by as much as 15 percent. Here, AI becomes a key enabler of smarter asset management.

Presented with a asset reliability issue pertaining to a gas compressor motor, a large multinational with an offshore platform had experienced 24 months of constant tripping. Each tripping incident incurred a 24 hours shutdown and the longest period without a tripping incident was just 14 days. Using an AI platform to process 12 months of data, it was able to successfully identify root cause of the problem in 45 minutes, identifying two main contributors to the tripping. Upon resolving the two issues, the motor ran continuously for four months before another trip incident occurred (which was due to human error, rather than machine failure). It’s estimated that millions of dollars of downtime were avoided thanks to the use of AI to enable root cause analysis and predictive analysis.

Because of the storage limitations of electricity, for optimal efficiency it’s imperative that generation match consumption at any given time. Load forecasting is, of course, a difficult and complex task to master – but one where AI has the potential to make a significant impact. Accurate load forecasting can enable generators to optimize the mix of generating units that can serve the expected load while minimizing the production costs. A variety of external factors also impact load requirements – things like the weather, the day of the week, seasonality, or hour the of the day. Using AI and its ability to synthesize information from a variety of disparate, historical datasets to identify patterns, the ability for predictive analytics to accurately identify the next day’s load can be drastically improved.

AI has applications that can drive the reliability and robustness of power grids. Predictive analytics powered by machine learning, can, with high degrees of accuracy predict when equipment failure may occur by comparing expected operation to actual operation. Anomalies detected can provide meaningful, actionable insight, often within minutes. With the just-in-time maintenance that AI enables, asset failure can be prevented - for energy companies this could mean avoiding outages altogether, as AI moves maintenance from reactive to predictive.

You might think that Ironman's AI assistant, Jarvis, is farfetched - but more rudimentary versions are already in play. Royal Dutch Shell is one energy company that has been investing heavily in AI. Shell employs an AI assistant for customers which is available around the clock to answer frequently asked lubricant-related questions. According to Shell, the assistant handles more than 100,000 data sheets for 3,000 products, understands 16,500 physical characteristics of lubricants, and provides information on 18,000 different pack sizes.

We've said it once and we'll say it again - AI complements rather than replaces human intelligence. Lots of these tools and techniques are already being used today. And while AI doesn’t have all the answers to the future of energy, the businesses that start adapting and integrating AI technology into their operations right now certainly stand a better chance of meeting the challenges ahead.

Learn the differences between predictive, preventive, and reactive maintenance. Compare costs, benefits, and risks

Read ArticleHow to confidently move from pilot to enterprise-wide AI adoption

Read ArticleInterested in a demo of one of our data solution products?

DataHUB4.0 is our enterprise data historian solution, OPUS is our Auto AI platform and OASIS is our remote control solution for Smart Cities and Facilities.

Book your demo with our team today!

Complete the form below and we’ll connect you with the right VROC expert to discuss your project. Whether you’re launching a pilot, scaling AI across your enterprise, or integrating complex systems, we’ll help you turn your data into actionable insights—fast, efficiently, and with confidence.

The efficient deployment, continuous retraining of models with live data and monitoring of model accuracy falls under the categorisation called MLOps. As businesses have hundreds and even.

Learn more about DataHUB+, VROC's enterprise data historian and visualization platform. Complete the form to download the product sheet.

Learn how OASIS unifies your systems, streams real-time data, and gives you full control of your smart facility—remotely and efficiently. Complete the form to access the product sheet.

Discover how OPUS, VROC’s no-code Industrial AI platform, turns your operational data into actionable insights. Complete the form below to access the product sheet and learn how you can predict failures, optimise processes, and accelerate AI adoption across your facility.

Interested in reading the technical case studies? Complete the form and our team will be in touch with you.

Subscribe to our newsletter for quarterly VROC updates and industry news.