Maintenance is a necessary operating expense for process industries. However maintenance costs frequently spiral out of control, effecting the bottom line, especially when assets become unreliable and unplanned downtime occurs. In fact a single hour of unplanned downtime for oil and gas plants costs nearly $500,000, with unplanned downtime each year accounting for 20% of operating budgets.

Therefore the maintenance strategy employed is critical, as it directly impacts operational costs, safety, and ultimately productivity and the bottom line.

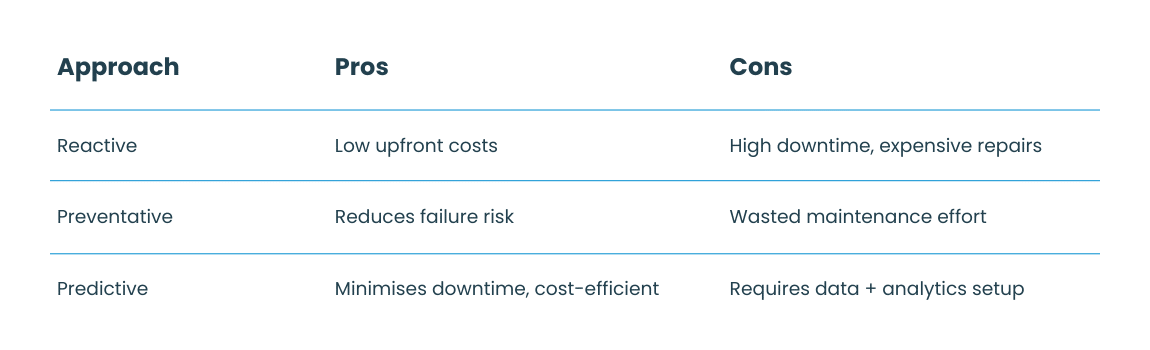

In this guide, we’ll break down reactive, preventive, and predictive maintenance, explain when each is best utilised, and show how AI-driven predictive maintenance offers the best results for modern process industries.

Related reading: Predictive Maintenance - AI & Machine Learning Solutions

Reactive maintenance has long been the traditional approach to maintenance in various industries. This method involves waiting for a piece of equipment to break down before taking any action. While it may seem like a cost-effective strategy in the short term, it often leads to higher expenses and downtime in the long run.

Definition: Assets are repaired or replaced only after they fail.

When it’s used: For non-critical, low-cost equipment where downtime has minimal impact.

Pros: Low upfront investment; minimal planning.

Cons: High unplanned downtime, emergency repair costs, and safety risks.

Preventative maintenance is scheduled maintenance regardless of the equipment’s condition and output. The purpose behind a preventative approach is to prevent failures and extend the assets lifespan. Whilst a preventative method sounds ideal, there is the question of the necessity of maintenance on equipment that is functioning and outputting sufficiently.

Definition: Scheduled maintenance based on time intervals, usage hours, or mileage, regardless of actual condition.

When it’s used: Widely used for fleets, utilities, and manufacturing assets.

Pros: Reduces unexpected failures; predictable scheduling.

Cons: Wasted resources if components are replaced too early; may not prevent unexpected issues.

The predictive maintenance method looks to forecast and predict when failure is going to happen, and allow sufficient time for maintenance to be scheduled and parts to be ordered before the failure takes place.

Definition: Uses real-time and historical data, often powered by AI/ML, to forecast when maintenance is actually required.

When it’s used: For critical, high-value assets where uptime is essential.

Pros: Maximises uptime, reduces costs, extends asset life, improves safety.

Cons: Requires data collection and analytics capabilities.

Traditional preventive and reactive strategies are giving way to predictive maintenance, driven by advances in AI and machine learning which have lead to prediction accuracy and therefore maintenance savings.

VROC’s no-code platform uses automated machine learning and AI to:

Analyse millions of data points from sensors and historians

Detect anomalies weeks or months before failures occur

Explain model outputs so engineers can make informed decisions

Continuously improve accuracy without manual coding

Example: In one case, VROC detected a mechanical seal failure on a produced water pump, predicting failure in 5 days — the customer avoided £1,000,000 in potential downtime losses, by scheduling a pump changeover and maintenance.

Learn how AI predictive maintenance reduced downtime - download our guide

Most organisations use a mix of strategies depending on asset criticality, cost, and risk tolerance:

Low-value assets – Reactive

Mid-value, predictable wear – Preventive

Critical, expensive assets – Predictive

With machine learning, predictive maintenance is no longer complex or resource-heavy. Platforms like VROC enable operations teams to:

Deploy AI models without coding or technical expertise

Integrate with existing systems

Monitor performance across entire sites or enterprises (even for mid-value and low-value assets)

Download Whitepaper: How AI Predicts Failures Before They Happen

Explore three early signs of equipment deviation that are commonly missed — and how real‑time, multivariate AI models can help reliability teams detect, diagnose, and act.

Read ArticleHow to confidently move from pilot to enterprise-wide AI adoption

Read ArticleInterested in a demo of one of our data solution products?

DataHUB4.0 is our enterprise data historian solution, OPUS is our Auto AI platform and OASIS is our remote control solution for Smart Cities and Facilities.

Book your demo with our team today!

Complete the form below and we’ll connect you with the right VROC expert to discuss your project. Whether you’re launching a pilot, scaling AI across your enterprise, or integrating complex systems, we’ll help you turn your data into actionable insights—fast, efficiently, and with confidence.

The efficient deployment, continuous retraining of models with live data and monitoring of model accuracy falls under the categorisation called MLOps. As businesses have hundreds and even.

Learn more about DataHUB+, VROC's enterprise data historian and visualization platform. Complete the form to download the product sheet.

Learn how OASIS unifies your systems, streams real-time data, and gives you full control of your smart facility—remotely and efficiently. Complete the form to access the product sheet.

Discover how OPUS, VROC’s no-code Industrial AI platform, turns your operational data into actionable insights. Complete the form below to access the product sheet and learn how you can predict failures, optimise processes, and accelerate AI adoption across your facility.

Interested in reading the technical case studies? Complete the form and our team will be in touch with you.

Subscribe to our newsletter for quarterly VROC updates and industry news.