Around the world industrial businesses are need to identify ways to improve their energy performance, efficiency, usage, and consumption. Many asset-intensive businesses have decided to implement IOS 50001:2018 or have rolled out energy management systems (EnMs) into their overall efforts to improve quality and environmental management as part of their business strategy.

It is essential for organisations to plan and efficiently manage their energy performance, to meet their carbon reduction goals, along with their reputation management and competitiveness in the market.

A core component of an energy management system is the ability to gather data from a variety of unconnected sources and analyse it to make informed decisions for the continual improvement of energy performance. Due to the large volume of data that industrial businesses produce every hour, and the global scale of many organisations, manually measuring and identifying areas of significant energy use can be difficult.

Artificial intelligence assists companies to rapidly analyse their industrial data, and can help them in the following nine ways;

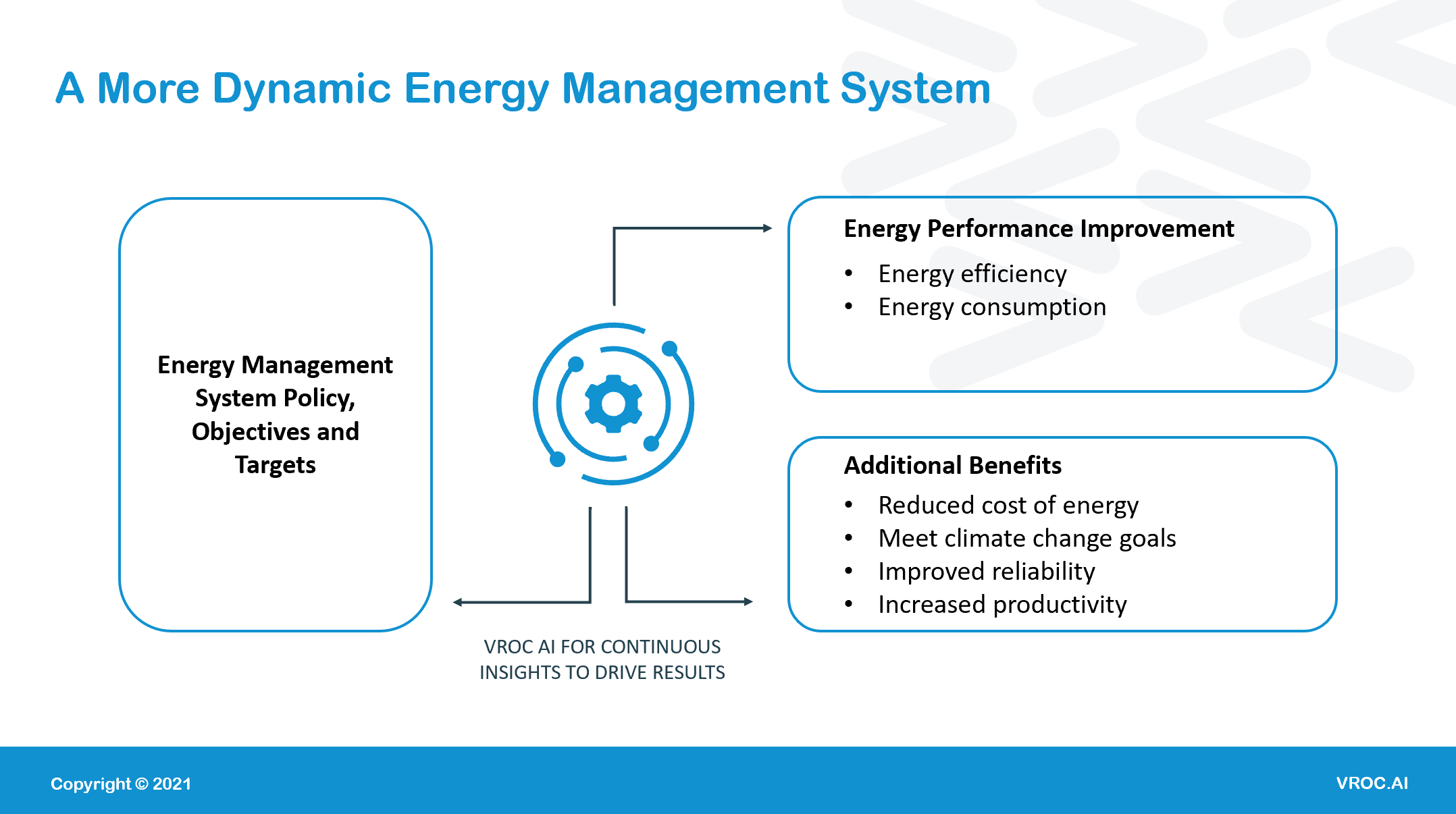

By supporting an energy management system with a powerful AI platform, companies can uncover automatic insights to drive continued energy performance improvement.

EnMs and AI can be implemented by a broad range of energy-intensive industries, from oil and gas, mining and resources, manufacturing, water utilities and power generation, among others.

One of VROC’s clients used AI to compare two identical assets. The VROC platform, OPUS was able to identify a deviation on one of the assets which was causing excessive energy consumption and reliability issues. The client was able to intervene and optimise the asset, improving heat retention which was estimated to save $280,000 USD annually in reduced fuel consumption.

In another example, AI was used to forecast the supply of energy in a state-wide grid. Initially tasked to forecast 72hours in advance, the no-code AI platform was able to automatically forecast 7 days in advance, using the available historical plant data as well as weather data. It is estimated that improving the accuracy of forecasting by 1%, and not oversupplying or undersupplying the market, can result in an estimated $800M AUD savings annually in the industry.

As companies enrich their energy management system with artificial intelligence, energy performance improves, along with additional benefits such as improved asset reliability, increased productivity, reduced emissions and reduced OPEX costs.

If you would like to know more about how AI can assist in your implementation of ISO 50001:2018, or integrate and enhance your existing energy management system please get in touch with our team.

With AI analytics, the mining industry can monitor and generate insights on their carbon emissions to help them plan today for a better tomorrow.

Read ArticleIt's no secret that our lives, work and world are being digitally transformed. But what does this mean for the planet? And what role can AI play in making the world safer, cleaner, happier and healthier?

Read ArticleInterested in a demo of one of our data solution products?

DataHUB4.0 is our enterprise data historian solution, OPUS is our Auto AI platform and OASIS is our remote control solution for Smart Cities and Facilities.

Book your demo with our team today!

Ready to embark on a pilot project or roll-out AI innovation enterprise wide? Perhaps you need assistance integrating your systems or storing your big data? Whatever the situation, we are ready to help you on your digital transformation.

The efficient deployment, continuous retraining of models with live data and monitoring of model accuracy falls under the categorisation called MLOps. As businesses have hundreds and even.

Learn more about DataHUB+, VROC's enterprise data historian and visualization platform. Complete the form to download the product sheet.

Discover how you can connect disparate systems and smart innovations in one platform, and remotely control your smart facility. Complete the form to download the product sheet.

'OPUS, an artistic work, especially on a large scale'

Please complete the form to download the OPUS Product Sheet, and discover how you can scale Auto AI today.

Interested in reading the technical case studies? Complete the form and our team will be in touch with you.

Subscribe to our newsletter for quarterly VROC updates and industry news.