Offshore oil and gas platforms operate in one of the most complex and high‑risk industrial environments. Equipment failures don’t just lead to maintenance costs — they can result in lost production, safety risks, and significant operational disruption.

This article explores how artificial intelligence (AI) and machine learning were applied on an offshore oil and gas platform to move from reactive and preventive maintenance toward a predictive, data‑driven operating model, enabling engineers to act earlier, with greater confidence.

• Earlier detection of equipment degradation before alarm thresholds were reached

• Reduced unplanned downtime and production losses

• Improved visibility into failure drivers at a sensor level

• Greater confidence in maintenance and operational decision‑making

Offshore platforms rely on a wide range of rotating and static equipment — compressors, pumps, generators, and utilities — all operating under harsh environmental and process conditions.

Common challenges include:

• Limited access to equipment, making reactive maintenance costly and slow

• High volumes of time‑series sensor data with limited analytical context

• Traditional rule‑based alarms that trigger too late or generate false positives

• Siloed engineering knowledge that is difficult to scale across assets

While preventive maintenance strategies help reduce risk, they are often based on fixed schedules rather than actual asset condition — leading to unnecessary maintenance or missed early‑stage failures.

Conventional condition monitoring and threshold‑based systems rely on known failure modes and predefined limits. However, many critical failures develop gradually and manifest as subtle changes across multiple sensors long before an alarm is triggered.

In offshore environments, this results in:

• Late detection of developing faults

• Increased reliance on expert interpretation

• Missed opportunities to intervene earlier and more safely

This is where machine learning offers a fundamentally different approach.

Using historical and live process data, machine learning models were developed to learn what normal operation looks like for specific assets under varying operating conditions.

Rather than relying on fixed thresholds, the AI models continuously monitored patterns across multiple sensors to identify early deviations from expected behaviour.

Key characteristics of the approach included:

• No reliance on predefined failure rules

• Models trained on real operating data from the platform

• Continuous learning as conditions changed

• Predictions delivered with contextual information for engineers

This allowed the system to highlight emerging issues well before traditional alarms were triggered.

A critical requirement for offshore operations is trust in the output. The AI did not operate as a black box.

For every prediction, engineers could:

• See which sensors contributed most to the prediction

• Understand the direction and magnitude of change

• Validate insights against their operational knowledge

This transparency ensured engineers remained in control — using AI as a decision‑support tool rather than an automated replacement.

By identifying early‑stage equipment degradation, the platform was able to:

• Plan maintenance activities proactively

• Avoid unplanned shutdowns and emergency interventions

• Reduce operational risk and safety exposure

• Optimise maintenance resources and spare parts planning

The value was not just in predicting failure, but in enabling better decisions earlier in the asset lifecycle.

Download the whitepaper: How AI Detected a Produced Water Pump Failure

To illustrate the power of AI in their operations, the client has shared three specific examples where AI saved time, resources, and money:

The plant’s flash gas compressor tripped, causing a significant increase in gas flaring. The team used OPUS to build an AI-driven probability model, pinpointing the root cause in a single session, bringing the compressor back online faster than ever. This saved 14 million cubic feet of gas from being flared, equating to a cost savings of $26,000.

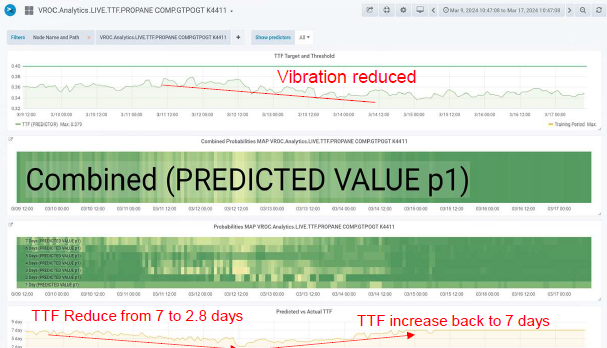

An engineer detected an anomaly in the propane compressor’s vibration levels using AI-based models. The team identified the issue—related to the male rotor position high vibration—and took corrective action before the situation escalated. By preventing a prolonged vibration event, they avoided significant equipment damage and potential losses of up to $23,400 per day.

The AI models predicted a shorter lifespan for an air filter on one of the platform’s gas turbines. By acting on this prediction, the team prevented a total plant blackout, which could have led to losses ranging from $23,400 to $46,800 per day. The ability to plan maintenance based on AI predictions ensured minimal disruption to the operation.

Several key learnings emerged from this implementation:

• Data quality and context matter more than model complexity

• Engineers must be involved throughout the model lifecycle

• Explainability is essential for operational adoption

• AI delivers the most value when embedded into existing workflows

Rather than replacing engineering expertise, AI amplified it — making insights more accessible and scalable across assets.

As offshore assets continue to age and operational pressures increase, predictive AI provides a practical pathway to improve reliability, safety, and performance.

By combining machine learning with deep process understanding, operators can move beyond reactive responses and static maintenance schedules toward a more resilient, data‑driven operating model.

Download the whitepaper: How AI Predicts Failures Before They Happen to explore how predictive models detect early‑stage degradation across complex industrial assets — and how engineers stay firmly in control of the decision‑making process.

Or explore how VROC supports predictive maintenance and operational optimisation across oil and gas assets.

Explore three early signs of equipment deviation that are commonly missed — and how real‑time, multivariate AI models can help reliability teams detect, diagnose, and act.

Read ArticleLearn the differences between predictive, preventive, and reactive maintenance. Compare costs, benefits, and risks

Read ArticleInterested in a demo of one of our data solution products?

DataHUB4.0 is our enterprise data historian solution, OPUS is our Auto AI platform and OASIS is our remote control solution for Smart Cities and Facilities.

Book your demo with our team today!

Complete the form below and we’ll connect you with the right VROC expert to discuss your project. Whether you’re launching a pilot, scaling AI across your enterprise, or integrating complex systems, we’ll help you turn your data into actionable insights—fast, efficiently, and with confidence.

The efficient deployment, continuous retraining of models with live data and monitoring of model accuracy falls under the categorisation called MLOps. As businesses have hundreds and even.

Learn more about DataHUB+, VROC's enterprise data historian and visualization platform. Complete the form to download the product sheet.

Learn how OASIS unifies your systems, streams real-time data, and gives you full control of your smart facility—remotely and efficiently. Complete the form to access the product sheet.

Discover how OPUS, VROC’s no-code Industrial AI platform, turns your operational data into actionable insights. Complete the form below to access the product sheet and learn how you can predict failures, optimise processes, and accelerate AI adoption across your facility.

Interested in reading the technical case studies? Complete the form and our team will be in touch with you.

Subscribe to our newsletter for quarterly VROC updates and industry news.