Most weeks we chat with a reliability engineer or maintenance supervisor and we ask – which asset or part of your plant provides you with the greatest challenge at the moment? Quite often, the response is the same – gas compressor reliability!!!

We hear about gas compressors that trip repeatedly, sometimes as often as every two days, others at least once a fortnight. The flow on effect of these sudden trips is a significant loss of production as well as an increased risk to personnel safety.

Industrial gas compressors are an integral component of chemical processing, transmission, air conditioning and natural gas propulsion plants. Depending on their application, they may be rotary, reciprocating, centrifugal or axial compressors. Gas compressors typically last 40,000 to 50,000 hours before requiring a major overhaul, and companies look to extend the total lifespan to 9 -10 years.

Depending on the type of gas compressor in use, there are a number of components that need to be maintained to ensure its on-going performance and reliability – seals, bearings, rotating shafts, discharge valves, cylinder heads, lube oil systems. Industrial maintenance teams typically use a combination of both preventative maintenance and condition monitoring to assist in ensuring the equipment is operational at all times.

Sensors installed on the gas compressors alert maintenance teams when it is operating out of specification allowing on-the-spot decisions to adjust operating parameters or if a failure seems imminent, to switch gas compressors (depending on availability). However, condition monitoring doesn’t predict future conditions, and despite best efforts equipment failures are often inevitable. Condition monitoring can cause many false alarms, whereby a condition has been met by the compressor that triggers an alarm, however the equipment can still operate perfectly under those conditions. The volume of these alarms can make it increasingly difficult for maintenance engineers to determine the root cause(s) and take swift and appropriate action to remedy the failure.

Preventative maintenance strategies are often based on the OEM’s recommendations which are typically over-cautious and can result in additional unnecessary maintenance work and costs. These are sometimes further refined based on criticality but are generally a time-based method without consideration of health and operating history of the asset.

In spite of preventative maintenance and condition monitoring, failures still persist across industrial operations worldwide. Maintenance teams and reliability engineers often struggle to find the root cause of these failures. Recurring problems may eventually get escalated to data science teams who perform data analytics on historical data to model specific problems and help identify the root cause. However, this work is retrospect in nature and may have little impact on future operating states and often is not captured as part of a “lessons learned” in the CMMS.

A client of VROC’s experienced a gas compressor trip once a fortnight. This problem continued for 2 years despite bringing in the OEM and SME to investigate and numerous focus groups internally to review the situation. Eventually this client decided to look to emerging technology, specifically AI for a solution. VROC’s AI platform ingested both live and historical data which was then structured, cleaned and went through an automated machine learning process that learns how the entire facility operates, not just the compressors. Using AI models, the system identified a number of causes that together were leading to the frequent trips , including an incorrect operating mode. Once these items were rectified within a few days, the gas compressor was put back into service and was finally shut down as part of a routine system shutdown four months later. This drastic change in the reliability and performance of the compressor provided a savings of about US$ 21.7M just over the four month period.

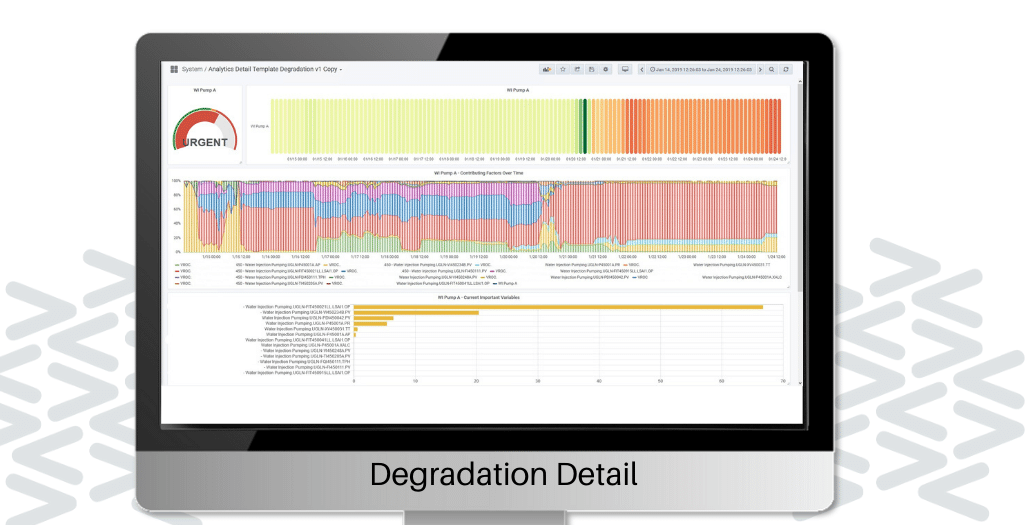

VROC AI learns from all available data, not just the normal range that is considered by traditional maintenance methodologies such as Condition Monitoring and Asset Specific AI modelling. It’s unique automated machine learning technology understands how equipment and processes operate under various operating conditions, identifying a wide range of influencing factors to performance and failures. Through constant learning from live data and trained models, VROC AI can predict future failures and outcomes, often up to days and weeks prior with a superior level of accuracy down to the component level. This provides the maintenance and reliability teams with insights that enable them to plan and implement predictive and prescriptive maintenance, avoiding failures and unplanned shutdowns.

In addition to assisting with the reliability of the asset, its lifespan can be increased with the use of complex AI models. The platform learns the optimal operating conditions and can provide optimization teams with insights to help them improve production rates, asset life expectancy and sustainability metrics.

If you are interested in learning how AI can help you increase the reliability and lifespan of your Gas Compressor or other criticial assets, get in touch for a demo.

Empowering decision making and operational efficiency with AI on an offshore platform in Central Asia.

Read ArticleInterested in a demo of one of our data solution products?

DataHUB4.0 is our enterprise data historian solution, OPUS is our Auto AI platform and OASIS is our remote control solution for Smart Cities and Facilities.

Book your demo with our team today!

Ready to embark on a pilot project or roll-out AI innovation enterprise wide? Perhaps you need assistance integrating your systems or storing your big data? Whatever the situation, we are ready to help you on your digital transformation.

The efficient deployment, continuous retraining of models with live data and monitoring of model accuracy falls under the categorisation called MLOps. As businesses have hundreds and even.

Learn more about DataHUB+, VROC's enterprise data historian and visualization platform. Complete the form to download the product sheet.

Discover how you can connect disparate systems and smart innovations in one platform, and remotely control your smart facility. Complete the form to download the product sheet.

'OPUS, an artistic work, especially on a large scale'

Please complete the form to download the OPUS Product Sheet, and discover how you can scale Auto AI today.

Interested in reading the technical case studies? Complete the form and our team will be in touch with you.

Subscribe to our newsletter for quarterly VROC updates and industry news.