Industrial Analytics, artificial intelligence and machine learning are all buzz words at the moment. Companies have spent big dollars jumping on the band wagon of AI, to be seen as innovative and forward thinking. However, with few companies scaling up their pilot programs, applying the technology enterprise wide and broadly reaping the benefits, we thought it timely to put together an article to assist in the selection of industrial analytics software.

First up, before we dive into how to select the best industrial analytics software, its important to establish what industrial analytics software is. Industrial analytics software is a powerful tool that enables businesses to gain valuable insights from their industrial operations. It collects and analyzes vast amounts of data generated by industrial processes, such as manufacturing.

By leveraging advanced analytics and machine learning techniques, industrial analytics software can identify patterns, detect anomalies, and predict potential issues, helping businesses optimize efficiency, reduce downtime, and make data-driven decisions. Choosing the right industrial analytics software is crucial for maximizing the benefits it can provide.

It’s important as you research your Industrial Analytics Software that you ask the following questions;

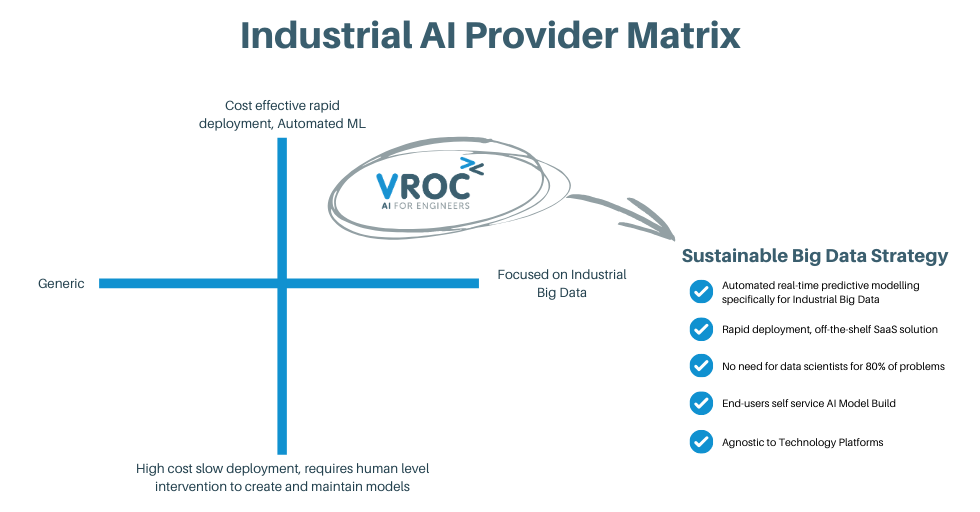

Most industrial analytics solutions fall into one or more of the following categories. Understanding these and their differences can help you understand if the solution is a good fit for your organisation. The four categories are: Generic AI Solutions, Consultative AI Solutions, Automated Machine Learning Solutions, and lastly Industrial Big Data Focused Solutions.

Some of the vendors provide advanced analytics and AI to a broad range of industries; from retail, banking, healthcare, telecommunications, aerospace, manufacturing and transportation. Artificial Intelligence can be applied to any type of big data and therefore a broad range of industries can benefit greatly.

VROC believes that customers benefit from an in-depth understanding of the industry and a clear understanding of their problems. For example, the problem statements being addressed in a retail or healthcare market are vastly different to those in oil and gas. Whilst there are benefits to diversification, there are risks of a diluted solution.

For industrial companies, we highly recommend you seek out AI providers that specialise in industrial time-series data and problem statements.

There are a number of data science consultancies who offer AI solutions, whose methodology revolves around a lengthy and costly consultative period. Spruced as highly customised solutions, these often take many months to develop and require human intervention to create and maintain models. Sadly, some customers are now reluctant to invest in digital transformation and AI altogether, since they previously engaged consultants, but never saw tangible results.

Whilst these providers offer domain knowledge, it is important to consider speed and cost of implementation.

There are a growing number of self-service, off-the-shelf solutions, which feature automated machine learning. This functionality does not rely on costly and lengthy data science consultations, meaning that results can be generated rapidly. The ‘self service’ component puts the power in the hands of domain and subject matter experts, who understand the problem statement being solved. No-code platforms, such as OPUS enable them to create their own artificial intelligence models without programming knowledge or expertise.

This solution releases data scientists to focus on the highly complex problems, whilst day-to-day problems are resolved by subject matter experts and engineers using the data insights obtained.

Automated machine learning has the advantage of learning from new data constantly, updating insights as it goes. When an incident occurs that has never happened before, the machine learning technology will learn all the triggers so it can predict similar occurrences in the future. This process is known as MLOps.

What makes industrial data so unique? It’s the shear volume of data produced by hundreds or thousands of sensors and controls, some of which produce time-series data every millisecond. This volume is mind-boggling. The industrial analytics software selected needs to be able to easily process this data rapidly.

Industrial assets are expensive, critical pieces of equipment, that often operate continuously. Slight improvements to production can mean a significant boost to the bottom line, and asset performance needs to be carefully modelled to predict deviations so interventions can be planned and faults avoided.

At VROC we are focused on industrial big data and automated machine learning.

Learn more about VROC's industrial analytics solution OPUS, along with case studies of the solution at work here for our industrial customers.

Dr Siavash shares insights into why asset failures are missed, and how AI helps Engineers see them earlier.

Read ArticleExplore three early signs of equipment deviation that are commonly missed — and how real‑time, multivariate AI models can help reliability teams detect, diagnose, and act.

Read ArticleInterested in a demo of one of our data solution products?

DataHUB4.0 is our enterprise data historian solution, OPUS is our Auto AI platform and OASIS is our remote control solution for Smart Cities and Facilities.

Book your demo with our team today!

Complete the form below and we’ll connect you with the right VROC expert to discuss your project. Whether you’re launching a pilot, scaling AI across your enterprise, or integrating complex systems, we’ll help you turn your data into actionable insights—fast, efficiently, and with confidence.

The efficient deployment, continuous retraining of models with live data and monitoring of model accuracy falls under the categorisation called MLOps. As businesses have hundreds and even.

Learn more about DataHUB+, VROC's enterprise data historian and visualization platform. Complete the form to download the product sheet.

Learn how OASIS unifies your systems, streams real-time data, and gives you full control of your smart facility—remotely and efficiently. Complete the form to access the product sheet.

Discover how OPUS, VROC’s no-code Industrial AI platform, turns your operational data into actionable insights. Complete the form below to access the product sheet and learn how you can predict failures, optimise processes, and accelerate AI adoption across your facility.

Interested in reading the technical case studies? Complete the form and our team will be in touch with you.

Subscribe to our newsletter for quarterly VROC updates and industry news.