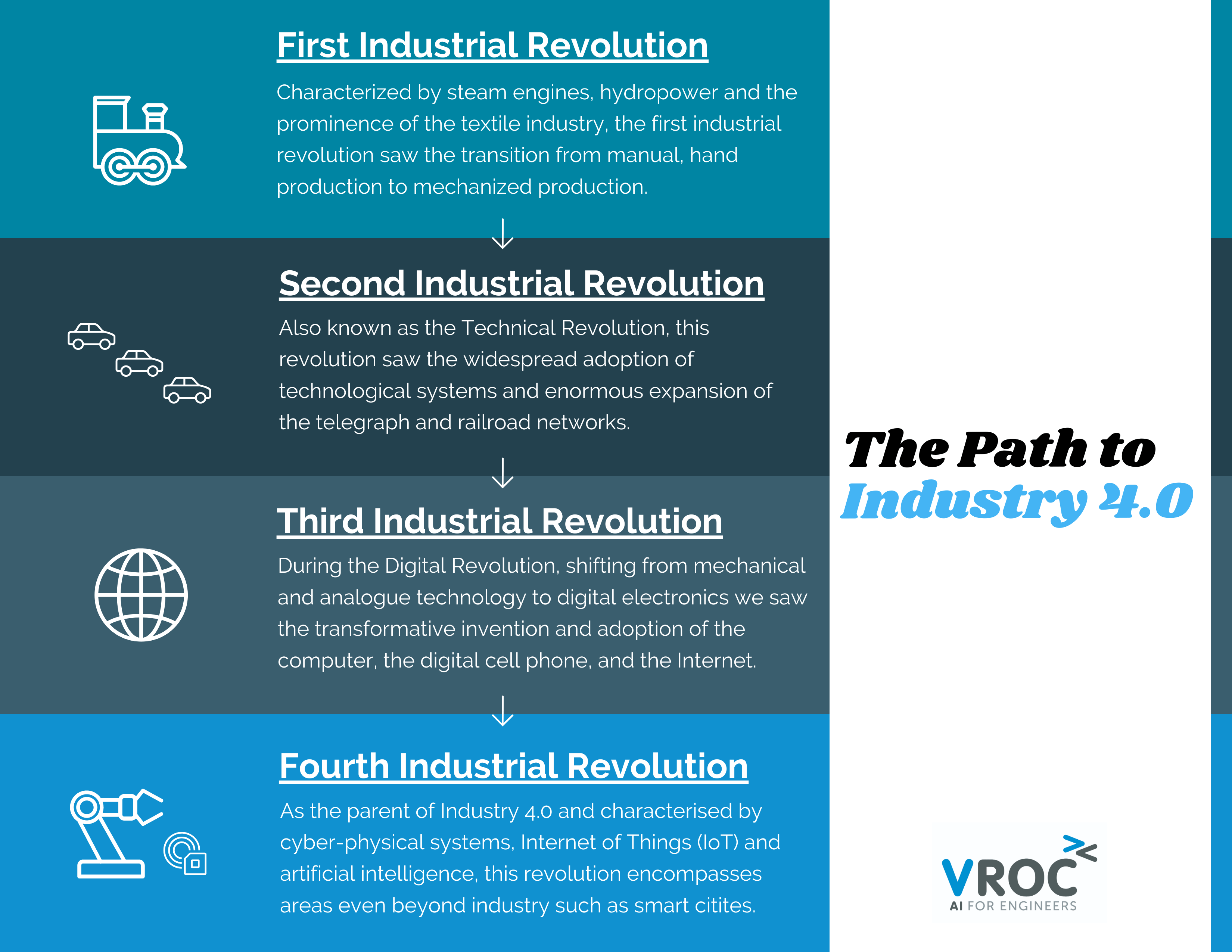

When the first industrial revolution hit, we were collectively amazed and irrevocably changed by the introduction of machines, powered by steam engines and hydropower. Now, a different revolution is taking place but machines are once again at the heart of the massive shift that's currently occurring. We're living in and through Industry 4.0 and what we're seeing is that this time, it's predictive technology that's driving us forward.

Industry 4.0 is a term that is often mistakenly interchanged with 'fourth industrial revolution'. In actual fact, it's a subset of the fourth revolution, focused more specifically on "the concept of factories in which machines are augmented with wireless connectivity and sensors, connected to a system that can visualise the entire production line, control, and make decisions on its own."

Industry 4.0 is all about data - how it's collected, analysed, synthesized, interpreted and applied. And that's why predictive maintenance and analytics is such a huge part of the Industry 4.0 - because it's all about using data to predict outcomes and improve performance. The AI technology that sits behind this comes with a variety of benefits that include job safety, environmental gains, increased productivity and uptime all of which typically results in supercharged ROI improvements.

" Industry 4.0 encompasses the pervasive trend towards automation and data exchange, internet of things (IoT), cloud computing, artificial intelligence and of course, predictive analytics. "

Through the lens of industry 4.0, predictive maintenance - which is in essence an extension and improvement of condition-based monitoring - is one of it's many positive outputs. By proactively and pre-emptively managing asset maintenance around predicted failures, uptime is significantly increased and productivity is majorly optimised.

The toolkit for making it possible comes in the form of AI-enabled analysis of big data. Using machine learning (a specific subset of artificial intelligence) it becomes a method of preventing asset failure by analyzing industrial production data to identify patterns and subsequently predict issues, breakages and failures before they happen.

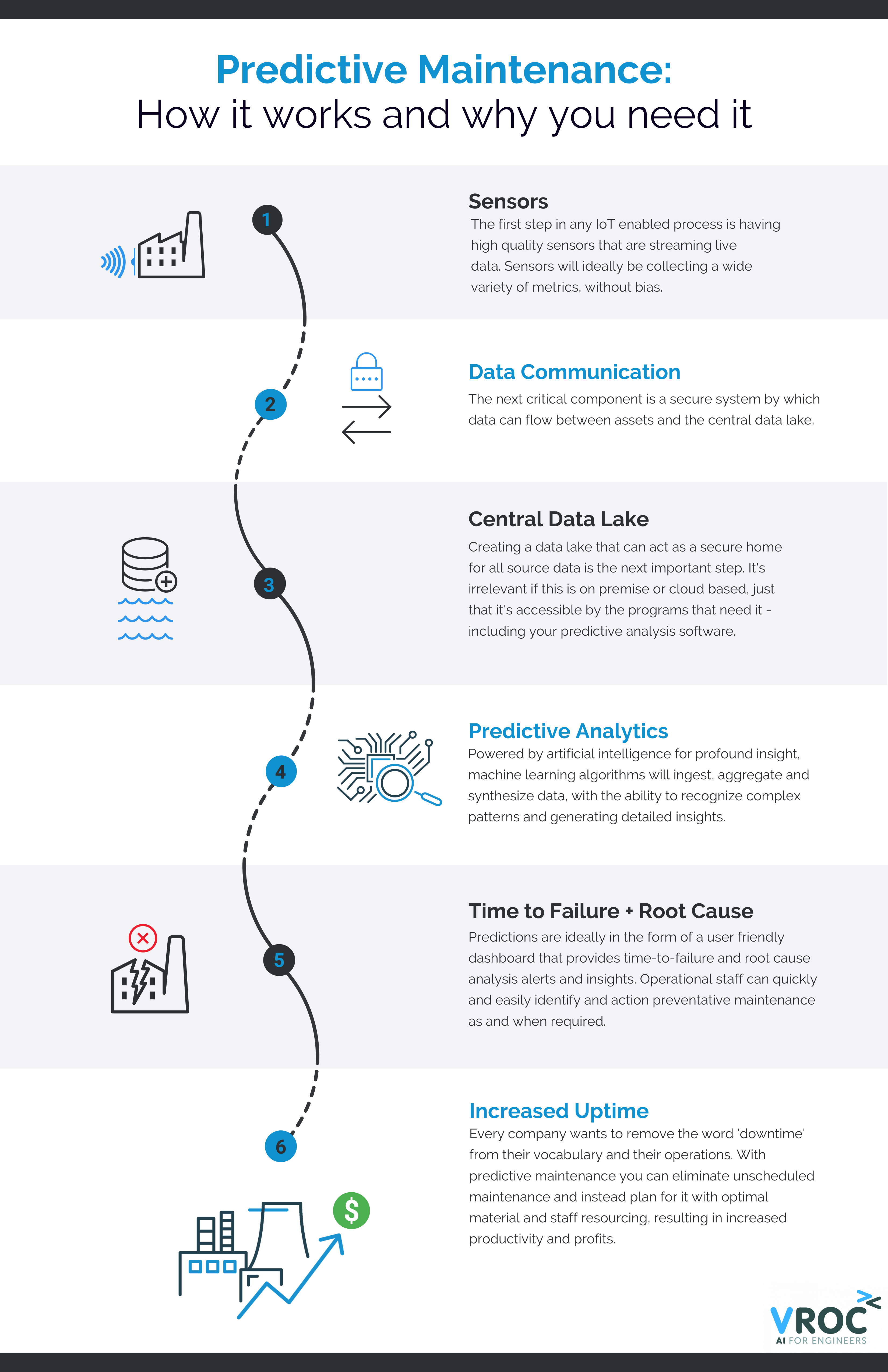

There are several components that must exist for an industrial asset to be predictively maintained and therefore considered Industry 4.0.

SENSORS

The first step in any IoT enabled process is having high quality sensors that are streaming live data. Sensors will ideally be collecting a wide variety of metrics, without bias. For assistance with sensor installation see DataEPIC.

DATA COMMUNICATION

The next critical component is a secure systems by which data can flow between assets and the central data lake.

CENTRAL DATA WAREHOUSE

Creating a data warehouse that can act as a secure home for all source data is the next important step. It's irrelevant if this is on premise or cloud based, just that it's accessible by the programs that need it - including your predictive analysis software. DataHUB4.0 has been uniquely designed for high volume industrial time-series data.

PREDICTIVE ANALYTICS

Powered by artificial intelligence for profound insight, machine learning algorithms will ingest, aggregate and synthesize data, with the ability to recognize complex patterns and generating detailed insights. OPUS, the no-code industrial AI platform is designed to produce predictive insights rapidly.

TIME TO FAILURE AND ROOT CAUSE ANALYSIS PREDICTIONS

Predictions are ideally in the form of a user friendly dashboard that provides time-to-failure and root cause analysis alerts and insights. Operational staff can quickly and easily identify and action predictive maintenance as and when required.

INCREASED UPTIME

Every company wants to remove the word 'downtime' from their vocabulary and their operations. With predictive maintenance you can eliminate unscheduled maintenance and instead plan for it with optimal material and staff resourcing, increasing productivity and profits.

Predictive maintenance is already playing a key role in Industry 4.0. As machines get smarter and AI technology and no-code platforms get more advanced, maintenance decisions will be increasingly left up to them to reduce the risk of human error and increase the chances of optimal performance. VROC's clients are already experiencing the benefits of using no-code AI for predictive maintenance, such as predicting the failure of a boiler pump and being able to avoid the failure. This and many other examples can be explored in our case studies.

Data - the currency of our age - is already and will continue to usher in a new era of industrial operations, smart factories and revolutionised ways of working.

As more and more companies recognize the value of implementing predictive maintenance, we will only see a faster gallop towards the end of Industry 4.0 and the start of whatever comes next.

Unplanned Shutdowns and downtime is bad for businesses. Can AI turn the dial?

Read ArticleArtificial intelligence provides critical insights for improved maintenance and shutdown planning, increasing the reliability of industrial facilities, and reducing operational costs.

Read ArticleInterested in a demo of one of our data solution products?

DataHUB4.0 is our enterprise data historian solution, OPUS is our Auto AI platform and OASIS is our remote control solution for Smart Cities and Facilities.

Book your demo with our team today!

Ready to embark on a pilot project or roll-out AI innovation enterprise wide? Perhaps you need assistance integrating your systems or storing your big data? Whatever the situation, we are ready to help you on your digital transformation.

The efficient deployment, continuous retraining of models with live data and monitoring of model accuracy falls under the categorisation called MLOps. As businesses have hundreds and even.

Learn more about DataHUB+, VROC's enterprise data historian and visualization platform. Complete the form to download the product sheet.

Discover how you can connect disparate systems and smart innovations in one platform, and remotely control your smart facility. Complete the form to download the product sheet.

'OPUS, an artistic work, especially on a large scale'

Please complete the form to download the OPUS Product Sheet, and discover how you can scale Auto AI today.

Interested in reading the technical case studies? Complete the form and our team will be in touch with you.

Subscribe to our newsletter for quarterly VROC updates and industry news.