Ever wished you knew the moment your equipment started deviating from normal operation? Perhaps if you had the insight early, you could have adjusted a setting, topped up a level and realigned the course trajectory to avoid equipment downtime.

Large manufacturers have thousands of pieces of equipment and tens of thousands of sensors, each sending data through continuously, making it hard for operations teams to monitor each component. Up until now, manufacturers have relied on condition monitoring, which alerts an operator when a threshold has been met. However often this alert is too late and failure is imminent.

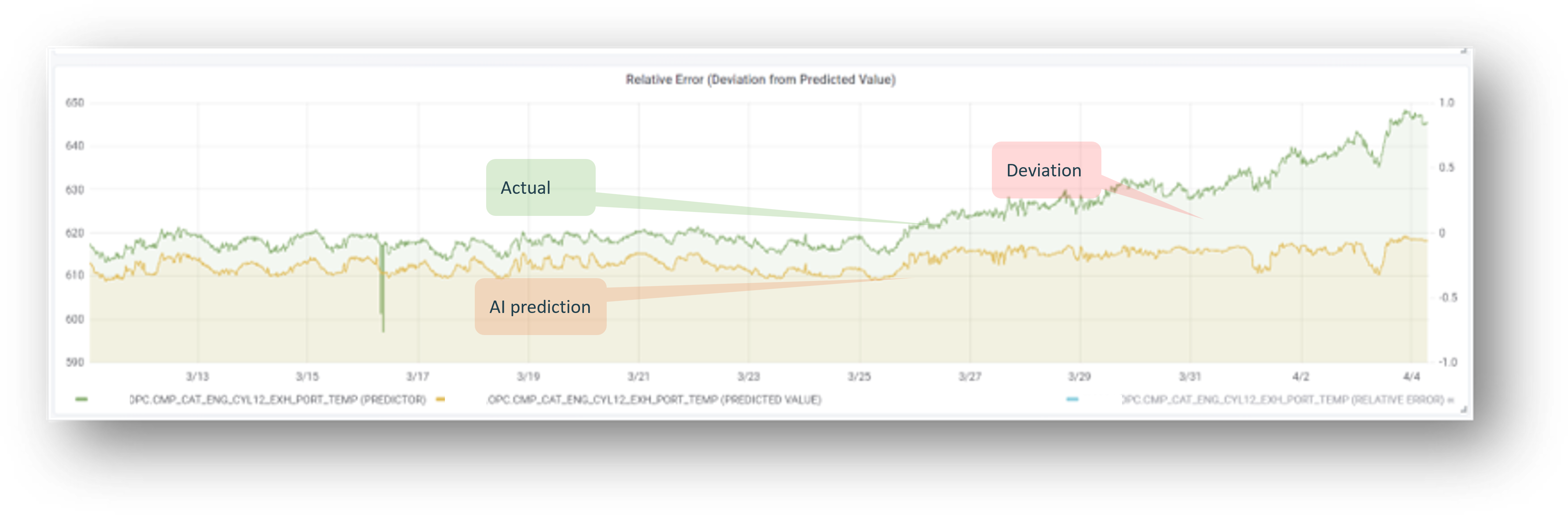

With artificial intelligence and machine learning technology, operators can predict the future performance of each system in their plant, detecting when a component of a piece of equipment deviates from normal operation. Deviations typically start out inconsequential, and the AI models study the trends, predicting if they are likely to cause issues or faults. By altering operations teams early, additional time is gained to plan necessary interventions.

VROC's AI platform OPUS includes a simple AI model wizard, which operators can use to build deviation models of their systems and processes, these models work tirelessly in the background continually forecasting equipment performance and predicting deviations.

Deviation Models learn from historical and real-time data to predict when a critical component of a process deviates from normal operation. This advance prediction provides time to plan interventions which leads to increased operational efficiency, reduced asset downtime, .

- Leaking non-driven end mechanical seal on a produced water pump

- Increased bearing vibrations of a Gearbox

- NDE bearing degradation on a water supply pump

- Gas air heater seal issue on coal fired power plant

- Boiler feed pump shaft bearing misalignment

- Ventilation fan rusted linkage

- Haul truck tyre degradation from sidewall cut

With VROC’s OPUS platform, building and deploying Deviation Models is a seamless process that doesn’t require any coding skills. Engineers and operators can utilize OPUS's model wizard to create sophisticated predictive models.

Whether you’re launching your first pilot or scaling AI across your enterprise, VROC’s end-to-end platform and expert team can help you unlock data, optimise performance, and accelerate results.

Interested in a demo of one of our data solution products?

DataHUB4.0 is our enterprise data historian solution, OPUS is our Auto AI platform and OASIS is our remote control solution for Smart Cities and Facilities.

Book your demo with our team today!

Complete the form below and we’ll connect you with the right VROC expert to discuss your project. Whether you’re launching a pilot, scaling AI across your enterprise, or integrating complex systems, we’ll help you turn your data into actionable insights—fast, efficiently, and with confidence.

The efficient deployment, continuous retraining of models with live data and monitoring of model accuracy falls under the categorisation called MLOps. As businesses have hundreds and even.

Learn more about DataHUB+, VROC's enterprise data historian and visualization platform. Complete the form to download the product sheet.

Learn how OASIS unifies your systems, streams real-time data, and gives you full control of your smart facility—remotely and efficiently. Complete the form to access the product sheet.

Discover how OPUS, VROC’s no-code Industrial AI platform, turns your operational data into actionable insights. Complete the form below to access the product sheet and learn how you can predict failures, optimise processes, and accelerate AI adoption across your facility.

Interested in reading the technical case studies? Complete the form and our team will be in touch with you.

Subscribe to our newsletter for quarterly VROC updates and industry news.