In industrial operations, understanding the health of your equipment in real time can be the difference between smooth production and costly downtime. This is where Industrial IoT (IIoT) networks come in — enabling businesses to monitor equipment remotely, detect anomalies early, and optimize maintenance before failures occur.

But how does it all work? Let’s break it down.

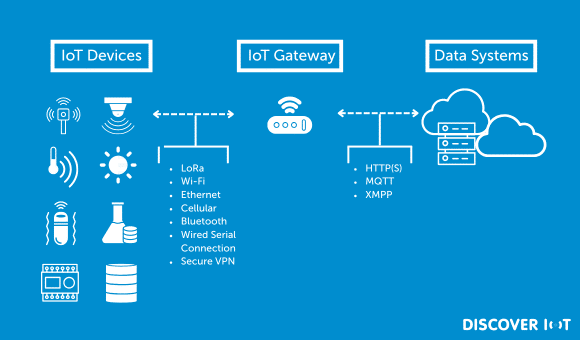

An IIoT network is made up of three key components:

1. Sensors – to collect data from physical assets

2. Gateways – to securely transmit data

3. Data Systems – to process, visualize, and act on the data

Think of it like this: sensors are the "ears and eyes," gateways are the "messengers," and the platform is the "brain" that makes sense of everything.

Industrial wireless IoT sensors attach to your machinery — without any invasive installations or disruptions to operations. They monitor key metrics such as:

· Vibration and acceleration

· Temperature

· Speed and frequency

· Sound

These sensors, like the ones available in VROC’s Discover IoT solution, are built tough for hazardous environments —waterproof and dustproof, battery-powered with up to 3 years of life, and magnetically attach to equipment for easy deployment.

Where equipment data already exists, it can be incorporated into the IoT network from PLC, DCS, Historian, SCADA through VPN or wired connection from the machine itself.

Once your sensor collects data, it needs to send it somewhere. That’s the role of the IoT gateway.

VROC’s industrial-grade gateways are designed to:

• Connect sensors within a 2.5km radius

• Transmit data over cellular or satellite networks - built-in SIM cards mean no IT network required!

• Offer multiple communication interfaces, including:

o Gigabit Ethernet

o Dual-band WiFi

o Bluetooth 5.0

o GPS for asset location tracking

o Wired serial connection

o LoRa

This gives you flexible deployment options, especially in remote or disconnected environments like mines, solar farms, or offshore platforms.

And with edge computing capabilities, data can be processed locally at the gateway for faster alerts and reduced bandwidth needs.

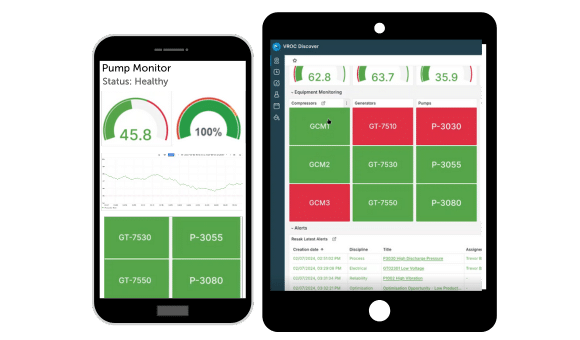

The gateway sends the data to VROC’s Discover IoT industrial hub, where it’s securely stored, visualized, and analyzed using applications custom built for your physical asset.

The applications allow operators to:

· Monitor equipment condition 24/7

· View historical trends

· Set alerts for anomalies or thresholds

· Monitor predictive insights produced by powerful AI models

· Non-invasive monitoring – no need interfere with machines or halt production

· Reliable connectivity – even in remote or hazardous areas

· Reduce unplanned downtime – early warning of equipment issues

· Fast deployment – sensors and gateways can be set up in hours

· Secure data transmission – over licensed LTE, LPWAN, or wired networks

· Scalable infrastructure – add sensors or locations as your needs grow

An industrial IoT network doesn’t need to be complex. With solutions like VROC’s Discover IoT, you gain a plug-and-play, scalable, and secure system that helps your team gain real-time visibility into critical assets — without needing a degree in networking or data science.

Whether you’re operating in oil and gas, mining, energy, or manufacturing, investing in the right IIoT foundation sets you up for smarter maintenance, better decisions, and more uptime.

Get in touch with our team today to get started with Discover IoT.

Interested in a demo of one of our data solution products?

DataHUB4.0 is our enterprise data historian solution, OPUS is our Auto AI platform and OASIS is our remote control solution for Smart Cities and Facilities.

Book your demo with our team today!

Complete the form below and we’ll connect you with the right VROC expert to discuss your project. Whether you’re launching a pilot, scaling AI across your enterprise, or integrating complex systems, we’ll help you turn your data into actionable insights—fast, efficiently, and with confidence.

The efficient deployment, continuous retraining of models with live data and monitoring of model accuracy falls under the categorisation called MLOps. As businesses have hundreds and even.

Learn more about DataHUB+, VROC's enterprise data historian and visualization platform. Complete the form to download the product sheet.

Learn how OASIS unifies your systems, streams real-time data, and gives you full control of your smart facility—remotely and efficiently. Complete the form to access the product sheet.

Discover how OPUS, VROC’s no-code Industrial AI platform, turns your operational data into actionable insights. Complete the form below to access the product sheet and learn how you can predict failures, optimise processes, and accelerate AI adoption across your facility.

Interested in reading the technical case studies? Complete the form and our team will be in touch with you.

Subscribe to our newsletter for quarterly VROC updates and industry news.