"We have prolonged the gas compressor reliability to four months, from a maximum of 2 weeks running. The GCM uptime has improved with the value of 21.7m USD.”

Head of Offshore Operations

VROC enables oil and gas operators to move beyond reactive maintenance and siloed monitoring by applying real-time, predictive AI across assets, processes, and sites. Engineers gain earlier insight into equipment degradation, clearer understanding of root cause, and the confidence to intervene before failures impact safety, production, or cost.

Oil and gas operations are increasingly complex—often operating across aging infrastructure, remote locations, and variable operating conditions. Traditional condition monitoring and rule-based systems struggle to keep pace with these realities.

Common challenges include:

Unplanned failures in rotating and critical equipment

Limited real-time visibility across dispersed assets and sites

High maintenance costs driven by reactive or conservative strategies

Complex interactions between process conditions and equipment health

Difficulty extending asset life in brownfield environments

VROC addresses these challenges through a unified, solution-led platform that connects monitoring, prediction, optimisation, and control.

Monitor equipment health, process conditions, and operational KPIs in real time—from offshore platforms and pipelines to processing facilities and terminals.

Capabilities include:

Integrated remote operations dashboards

KPI-to-sensor traceability for operational transparency

Alarm rationalisation and prioritisation

Real-time deviation management across processes

Asset geolocation and fleet-level visibility

This enables operators and engineers to see issues developing as they happen—not after production is impacted.

VROC’s predictive maintenance models learn normal operating behaviour and detect subtle deviations that signal early-stage equipment degradation—long before thresholds or alarms are breached.

Key outcomes:

Time-to-Failure (TTF) and Remaining Useful Life (RUL) forecasting

Multivariate root cause analysis at sensor and component level

Earlier intervention with greater confidence

Reduced unplanned downtime and maintenance costs

Extended asset life for aging and brownfield equipment

This approach supports reliability-centred maintenance without the burden of rule creation or constant tuning.

Use AI-driven digital twins and simulation to understand performance limits, test scenarios, and optimise operations under changing conditions.

Capabilities include:

Digital twin and what-if simulation

Sensitivity analysis and performance benchmarking

Energy and emissions optimisation

Identification of process inefficiencies and constraints

These insights help operators maximise production while maintaining safe and stable operations.

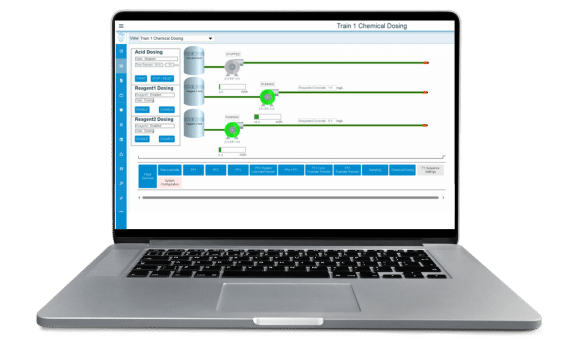

VROC connects predictive and optimisation insights directly to operational control through modern, web-based interfaces.

Capabilities include:

Web SCADA for monitoring and control

Integration with existing control systems

Operator-led decision support and execution

This ensures insights don’t stop at dashboards—they drive action.

Detect early-stage degradation in critical rotating equipment by learning normal operating behaviour across vibration, temperature, pressure, and process conditions. VROC predicts time-to-failure, identifies contributing components, and enables earlier, more targeted maintenance—reducing unplanned downtime and extending asset life.

Identify subtle process deviations before they escalate into production losses or safety events. VROC continuously monitors multivariate process behaviour, highlights abnormal operating patterns in real time, and pinpoints the parameters driving instability—supporting faster diagnosis and corrective action.

Provide a unified, real-time view of assets, processes, and KPIs across multiple sites and regions. VROC enables remote operations teams to monitor equipment health, prioritise alarms, track deviations, and support field teams with actionable insights—without relying on site-specific rules or manual analysis.

Track energy performance and emissions in real time to identify inefficiencies, abnormal consumption, and deviation from expected operating behaviour. VROC supports optimisation of energy use and emissions intensity while maintaining stable, reliable operations across facilities.

Extend the useful life of brownfield and aging assets by detecting degradation earlier and understanding the conditions that accelerate wear. VROC’s predictive models support informed decisions on maintenance, refurbishment, and operating limits—reducing capital pressure while maintaining reliability and safety.

Monitor and manage reliability across diverse fleets of equipment operating under varying conditions. VROC scales predictive maintenance and deviation management across mixed asset types, enabling consistent insight, prioritisation, and decision-making at fleet level.

VROC’s implementation approach is focused on operational impact:

Connect quickly to existing data sources

Build and deploy models in weeks, not months

Iterate with engineers and operators as conditions change

Scale across assets, sites, and entire operations

This ensures faster insight, faster adoption, and measurable value.

Client supply of historical data and set-up of real-time streaming

Data ingestion and real-time data streaming connection

Client training and model generation

Models in production. Client starts delivering business value

Discover how VROC helps oil and gas operators improve reliability, reduce downtime, and optimise production using predictive, real-time AI.

Explore Oil and Gas SolutionsWhether you’re launching your first pilot or scaling AI across your enterprise, VROC’s end-to-end platform and expert team can help you unlock data, optimise performance, and accelerate results.

Interested in a demo of one of our data solution products?

DataHUB4.0 is our enterprise data historian solution, OPUS is our Auto AI platform and OASIS is our remote control solution for Smart Cities and Facilities.

Book your demo with our team today!

Complete the form below and we’ll connect you with the right VROC expert to discuss your project. Whether you’re launching a pilot, scaling AI across your enterprise, or integrating complex systems, we’ll help you turn your data into actionable insights—fast, efficiently, and with confidence.

The efficient deployment, continuous retraining of models with live data and monitoring of model accuracy falls under the categorisation called MLOps. As businesses have hundreds and even.

Learn more about DataHUB+, VROC's enterprise data historian and visualization platform. Complete the form to download the product sheet.

Learn how OASIS unifies your systems, streams real-time data, and gives you full control of your smart facility—remotely and efficiently. Complete the form to access the product sheet.

Discover how OPUS, VROC’s no-code Industrial AI platform, turns your operational data into actionable insights. Complete the form below to access the product sheet and learn how you can predict failures, optimise processes, and accelerate AI adoption across your facility.

Interested in reading the technical case studies? Complete the form and our team will be in touch with you.

Subscribe to our newsletter for quarterly VROC updates and industry news.