The stable supply and management of the grid has become more complex with renewable generation sources and a commitment to reduce emissions without rising costs.

Utilities operators and energy generators are faced with the challenge to manage grid reliability, increase adoption of clean energy, and minimize costs.

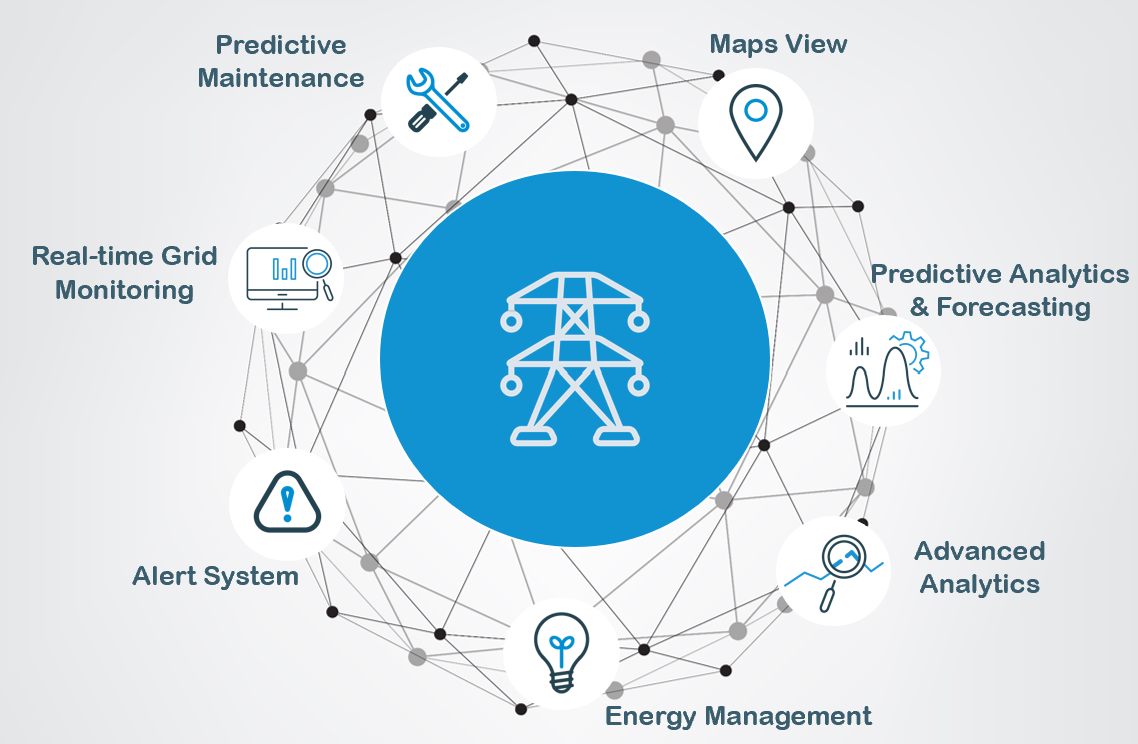

Demand and flexible load responses are helping to manage energy efficiency and when real-time and historical data is interconnected and AI technology is applied, the industry can be further optimized with the critical insights and predictions to optimize the grid both now and into the future.

For cost minimisation, operators and generators needs to address downtime, which Continuity Central report on average accounts for 32hrs a month, at a cost of $220,000 per hour. VROC OPUS can drastically improve asset reliability with AI predictive maintenance, allowing for maintenance to be planned, spares to be ordered and work implemented accurately first time, minimising disruptions to the network and reduce rising costs.

Insights acquired from advanced analytics can assist operators with energy management optimization, planning, monitoring, and reporting requirements, helping them meet their carbon reduction and sustainability goals.

Use AI to forecast your energy production hours and days in advance across your diversified network. AI models can factor in variables including real-time asset condition, weather volatility and historical data. Get alerts if production forecast falls beneath thresholds.

Smart grid control can be optimized through the real-time connection to all system components. Automated data collection, storage, processing and AI analytics can give grid operators greater insights into the current and future states to improve business decisions.

Reduce rising costs caused by asset failures and unplanned downtime with predictive maintenance insights. Early intervention and planned maintenance based on AI predictions can lead to significant operational cost savings, for some VROC customers, millions of dollars have been saved.

Client supply of historical data and set-up of real-time streaming

Data ingestion and real-time data streaming connection

Client training and model generation

Models in production. Client starts delivering business value

Whether you’re launching your first pilot or scaling AI across your enterprise, VROC’s end-to-end platform and expert team can help you unlock data, optimise performance, and accelerate results.

Interested in a demo of one of our data solution products?

DataHUB4.0 is our enterprise data historian solution, OPUS is our Auto AI platform and OASIS is our remote control solution for Smart Cities and Facilities.

Book your demo with our team today!

Complete the form below and we’ll connect you with the right VROC expert to discuss your project. Whether you’re launching a pilot, scaling AI across your enterprise, or integrating complex systems, we’ll help you turn your data into actionable insights—fast, efficiently, and with confidence.

The efficient deployment, continuous retraining of models with live data and monitoring of model accuracy falls under the categorisation called MLOps. As businesses have hundreds and even.

Learn more about DataHUB+, VROC's enterprise data historian and visualization platform. Complete the form to download the product sheet.

Learn how OASIS unifies your systems, streams real-time data, and gives you full control of your smart facility—remotely and efficiently. Complete the form to access the product sheet.

Discover how OPUS, VROC’s no-code Industrial AI platform, turns your operational data into actionable insights. Complete the form below to access the product sheet and learn how you can predict failures, optimise processes, and accelerate AI adoption across your facility.

Interested in reading the technical case studies? Complete the form and our team will be in touch with you.

Subscribe to our newsletter for quarterly VROC updates and industry news.