By 2030, operations optimisation is forecast to deliver the greatest economic value across IoT use cases. However, as highlighted by McKinsey, 40–60% of this value may remain unrealised due to one critical issue: interoperability.

In the current landscape, interoperability has become a key focus area, as most operational environments still suffer from varying degrees of fragmentation across their equipment, systems, and data architecture. This fragmentation has evolved over time, driven by the widespread use of proprietary technologies and legacy systems that were never intended to connect to modern digital platforms.

The inability of these systems to communicate results in serious consequences: reduced operational efficiency, underutilisation of data, diminished decision-making capabilities, and increased risk across cybersecurity, compliance, and IT complexity.

Conversely, a connected, interoperable IoT ecosystem enables seamless data flow, scalable digital transformation, and improved return on investment. Below, we examine the root causes of interoperability challenges and outline actionable approaches to overcome them.

Legacy systems often lack the digital outputs or communication protocols required to talk with contemporary IoT platforms. Without the ability to transmit real-time data, these systems become isolated from broader operational insights, limiting opportunities for automation, remote monitoring, and advanced analytics.

Solution:

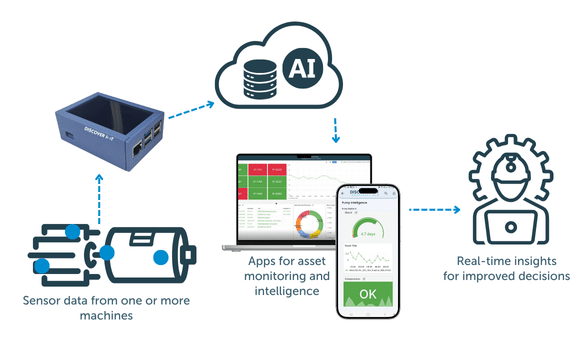

IoT gateways serve as protocol converters, enabling communication between legacy assets and modern platforms. Additionally, low-cost, industrial-grade IoT sensors can be retrofitted to ageing machinery to non-invasively collect essential data—such as temperature, vibration, or usage metrics—without modifying the equipment.

Older systems typically do not adhere to modern cybersecurity standards, lacking features such as encrypted communication, secure authentication, or hardened firmware. Connecting such systems to a networked IoT environment can introduce significant attack surfaces.

Solution:

Conduct a security audit prior to integration. Implement appropriate encryption, secure access controls, and multi-factor authentication. Segmentation strategies can also isolate high-risk systems within the broader network architecture.

Legacy systems were not built to accommodate the scale or speed of IoT data. As a result, their infrastructure can be overwhelmed by the demands of real-time analytics and machine learning.

Solution:

Not all legacy systems will require a full replacement; many will sustain a gradual modernisation. Focus on critical systems that can benefit from IoT connectivity and deploy scalable architectures with gateways and edge computing to offset processing loads, enabling coexistence between old and new systems.

Retrofitting or replacing legacy systems can be cost-prohibitive, particularly when these systems are entrenched in daily operations and require custom integration.

Solution:

The availability of low-cost sensors, edge IoT gateways, and IoT platforms reduces the capital investment needed. Focus on targeted deployments with clear ROI to build internal business cases for further investment.

There are a vast number of vendors offering proprietary solutions to the industry, utilising closed ecosystems. Often, these vendors have developed unique protocols and standards to differentiate their products, which unfortunately makes them incompatible with other systems, exacerbating the fragmentation and silos within the ecosystem. There are no universally mandated standards for interoperability that vendors must comply with, so organisations must carefully assess vendor offerings to avoid technological dead-ends. Prioritising open protocols and platforms with documented APIs is essential for future-proofing infrastructure.

To overcome fragmentation and achieve long-term success with IoT, it is essential to address interoperability at four key layers:

This layer ensures that devices from different manufacturers can communicate and function within the same environment. By adopting standardised communication protocols—such as MQTT, AMQP, OPC UA, HTTP, and CoAP—organisations reduce integration complexity and increase deployment flexibility.

Devices should be assessed for compatibility not only at the hardware level but also in terms of protocol support, configuration requirements, and update capabilities.

Network interoperability refers to the seamless operation of diverse networking components and infrastructures within a unified communication framework. It requires the ability for routers, switches, gateways, and edge devices to operate across diverse environments, regardless of vendor or proprietary configuration.

The use of open network operating systems and virtualised network functions can facilitate this interoperability. These solutions decouple hardware from software and enable cross-platform compatibility, reducing the reliance on specific vendors and ensuring that new networked devices can be onboarded without friction.

Data interoperability focuses on the standardisation and harmonisation of data structures, formats, and semantics to ensure meaningful exchange between systems. Industrial IoT environments often include devices that output data in multiple formats—JSON, XML, CSV, or proprietary structures—leading to inconsistent data representation and integration challenges.

To address this, organisations must:

Standardise data formats where possible

Implement common data schemas

Utilise transformation tools to map disparate data models into unified structures

By aligning how data is defined, stored, and transmitted across systems, businesses can ensure compatibility between platforms, support machine learning and analytics, and improve operational transparency.

Platform interoperability involves the ability of IoT platforms, control systems, and middleware layers to interface across multiple technologies. Middleware plays a central role in translating protocols, managing data flow, and integrating legacy systems with cloud or edge environments.

Modern middleware platforms should support:

Multi-protocol integration (e.g., Modbus, MQTT, OPC UA)

Edge-to-cloud architecture

Open APIs for third-party development and integration

Scalability across assets and geographies

The right middleware reduces the complexity of managing diverse devices and systems, acting as a unifying layer that simplifies deployment and long-term system evolution.

A Western Australian council required real-time visibility and remote control capabilities across several emergency pump stations. Rather than replacing the entire system, the project team implemented a lightweight IoT solution using industrial sensors and communication gateways. These components fed data to a centralised IoT platform, enabling remote condition monitoring, simple control functionality, and performance analytics.

Crucially, the solution was designed to be interoperable, capable of integrating with future smart city infrastructure, expanding sensor networks, or exporting data to other systems. This demonstrates how scalable and future-ready outcomes can be achieved through smart interoperability planning.

Plug-and-play industrial-grade sensors

Multi-protocol IoT gateways

A powerful centralised platform for remote monitoring, analytics, and AI-based predictive insights

By prioritising interoperability at every layer—from device to platform—VROC enables organisations to bridge the gap between legacy systems and next-generation digital operations without significant disruption or vendor lock-in.

How to confidently move from pilot to enterprise-wide AI adoption

Read ArticleLearn how Industrial AI delivers tangible ROI in maintenance, operations and efficiency—an executive’s guide to evaluating AI investment

Read ArticleInterested in a demo of one of our data solution products?

DataHUB4.0 is our enterprise data historian solution, OPUS is our Auto AI platform and OASIS is our remote control solution for Smart Cities and Facilities.

Book your demo with our team today!

Complete the form below and we’ll connect you with the right VROC expert to discuss your project. Whether you’re launching a pilot, scaling AI across your enterprise, or integrating complex systems, we’ll help you turn your data into actionable insights—fast, efficiently, and with confidence.

The efficient deployment, continuous retraining of models with live data and monitoring of model accuracy falls under the categorisation called MLOps. As businesses have hundreds and even.

Learn more about DataHUB+, VROC's enterprise data historian and visualization platform. Complete the form to download the product sheet.

Learn how OASIS unifies your systems, streams real-time data, and gives you full control of your smart facility—remotely and efficiently. Complete the form to access the product sheet.

Discover how OPUS, VROC’s no-code Industrial AI platform, turns your operational data into actionable insights. Complete the form below to access the product sheet and learn how you can predict failures, optimise processes, and accelerate AI adoption across your facility.

Interested in reading the technical case studies? Complete the form and our team will be in touch with you.

Subscribe to our newsletter for quarterly VROC updates and industry news.